appliances

Tuesday, November 1st, 2022

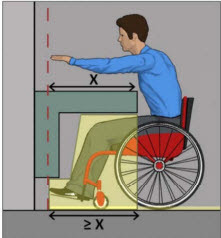

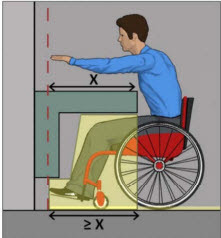

There seems to be a lot of confusion regarding the parallel (side) approach at sinks. The ADA, TAS and ANSI standards require all sinks and lavatories have a forward approach with a knee and toe clearance provided.

ADA and TAS (ANSI A117.1 similar) 606.2 Clear Floor Space. A clear floor space complying with 305, positioned for a forward approach, and knee and toe clearance complying with 306 shall be provided.

There are some exceptions that we will cover in this newsletter. Exceptions don’t have to be used, but if you need them, they are available.

Kitchen sinks WITHOUT a cook top or range

Exception 1. A parallel approach complying with 305 shall be permitted to a kitchen sink in a space where a cook top or conventional range is not provided and to wet bars.

The confusion in this exception is what is a “kitchen” sink. When there is not a clear definition in the definition section of the standards, they recommend that a dictionary definition may be used. TDLR did go on record as explaining what is their definition of kitchen with their Technical Memo TM2012-09.

In essense, a space with a fixed or built in cooking appliance will be considered a kitchen. And if the kitchen DOES NOT have a cooktop or range, then a parallel approach at the sink can be used.

The photo above is of a space with a built in oven. It is a built in cooking appliance, therefore it is considered a kitchen. Because this “kitchen” does not have a cook top or a range, the sink may have a parallel approach.

The photo above is of a space with a movable microwave oven on a shelf. Since the microwave is not built in, this is not considered a “kitchen” and a parallel approach cannot be used at the sink. The sink must have a forward appraoch with a knee and toe clearance as shown.

The photo above is of a space with a built in microwave oven and a built in range. This is considered a kitchen. And since it has a range, it cannot take the parallel approach exception and a knee clearance must be provided (as shown) at the sink.

The photo above is of a space with a microwave on the counter. Because the microwave is not built in, it is not considered a kitchen. Therefore, it cannot take the parallel approach exception and a knee clearance must be provided (as shown) at the sink.

Outdoor Kitchen Sinks

The photo below is of an outdoor kitchen for an office space. It is in essense an outdoor break area. The outdoor kitchen is scoped per TAS 212, 606, and 804. The sink is not eligible for 606.2 exception 1 because a fixed cooking facility is provided (grill). The parallel approach is not compliant because the kitchen does not meet the definition of a wet bar – it provides a fixed cooking facility and it is used as a range/cook top.

The photo above is of an outdoor break area with a sink and a range

Wet Bars

Exception 1. A parallel approach complying with 305 shall be permitted to a kitchen sink in a space where a cook top or conventional range is not provided and to wet bars.

Part of this exception allows a parallel approach if the sink is part of a “wet bar”. A wet bar is essentially a place where only drinks will be served or prepared. These most commonly occur at waiting rooms or at hotel rooms without kitchennettes.

The photo above is of “wet bar” at a waiting room in a clinic

Lavatory at a private bathroom (accessed from a private office)

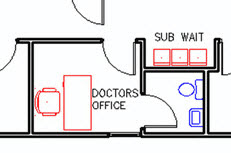

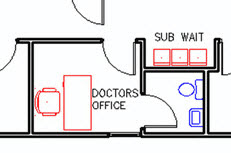

Exception 2. A lavatory in a toilet room or bathing facility for a single occupant accessed only through a private office and not for common use or public use shall not be required to provide knee and toe clearance complying with 306.

A office is deemed “private” if it is only for one person and not located in a common area. A “private” bathroom is deemed private if it is only accessed from the private office and only used by one person.

The image above is of a “private bathroom” that is accessed by a doctor’s office. The lavatory may take excepton 2

The photo above is of the lavatory at the private restroom that is accessed by a doctor’s office. The lavatory may take excepton 2 and can have a parallel approach.

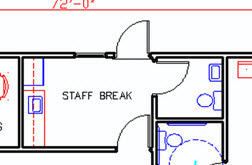

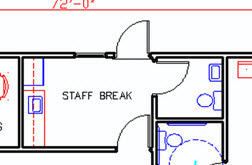

The image above is of a restroom accessed from the staff break room. This is NOT a private bathroom and the lavatory must have a forward approach w

ANSI A117.1, ADA and TAS Residential Lavatory and Kitchen Sinks

Exception 3. In residential dwelling units, cabinetry shall be permitted under lavatories and kitchen sinks provided that all of the following conditions are met:

(a) the cabinetry can be removed without removal or replacement of the fixture;

(b) the finish floor extends under the cabinetry; and

(c) the walls behind and surrounding the cabinetry are finished

This exception can be taken only at residential dwelling units. If it is taken a door can be used to cover the knee clearance, but the floor finish must extend to the back wall and the pipes must be protected. In addition the cabinetry must be able to be removed without having to re-build the knee clearance.

The image above shows a sink at a residential dwelling unit that has doors in front of the knee space. Once the doors are open, the floor finish and all the side walls around the sink are finished as well.

Sinks and lavatories for children 5 years old and younger

Exception 5. A parallel approach complying with 305 shall be permitted to lavatories and sinks used primarily by children 5 years and younger.

The image above shows a sink at a classroom for children five years old and younger

Upcoming Classes

November 17, 2022

8:30-9:30 a.m.

“Understanding and Complying with Barrier-Free Requirements in Outdoor Spaces” 1 HR HSW Barrier Free CEU

Webinar for HalfMoon Education

Monday, October 3rd, 2022

The ADA is not the only Standard that requires clear floor space to be centered. The Fair Housing Design Guidelines and ANSI A117.1 also does. This newsletter will provide guidance on when the clear floor space in a residential dwelling unit must be centered.

Fair Housing Kichen Appliances

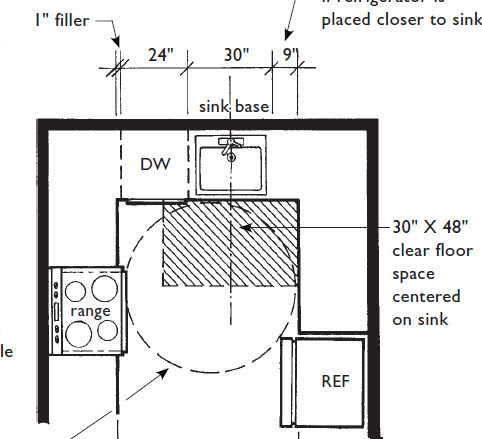

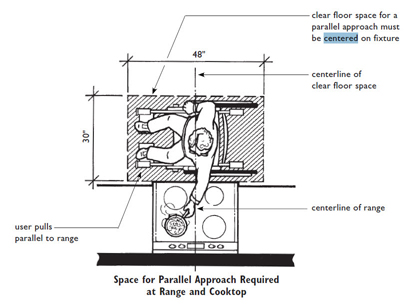

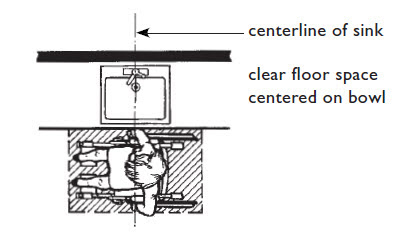

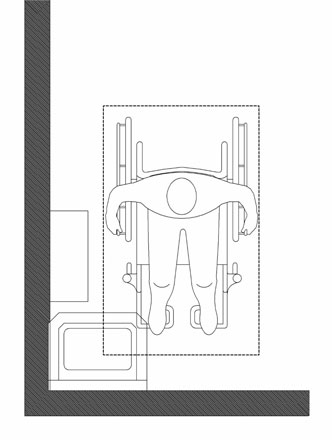

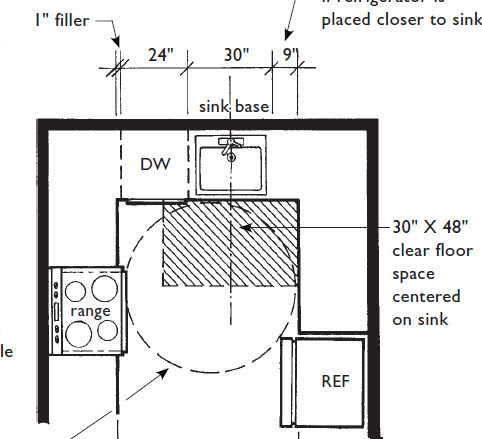

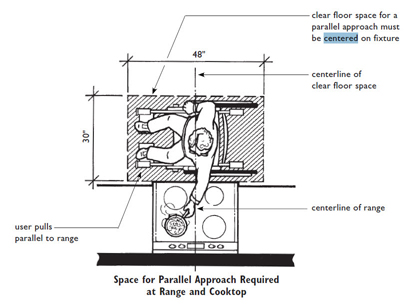

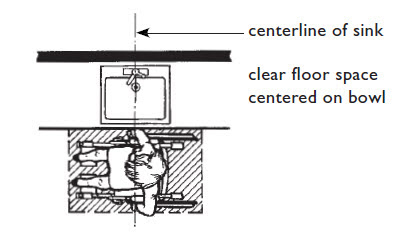

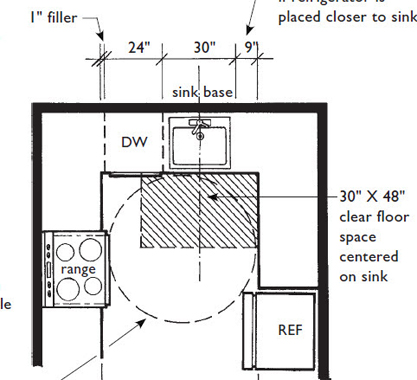

The parallel clear floor space at sinks, as at sink when bowls are ranges and cooktops, must be centered on the bowl of unequal size or appliance.

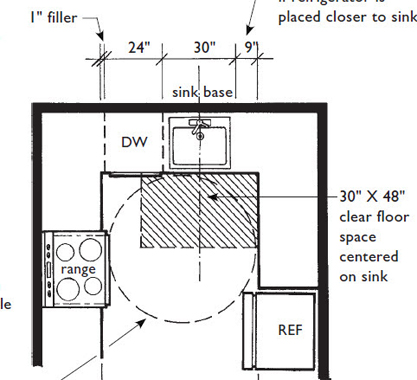

In addition to the turning space, the kitchen must be arranged so there is a 30-inch x 48-inch clear floor space for a parallel approach centered on the sink, range, or cooktop. The centerline of the fixture or appliance must be aligned with the centerline of the clear floor space.

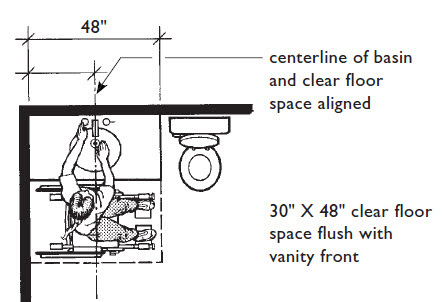

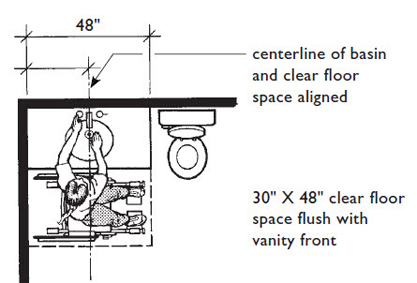

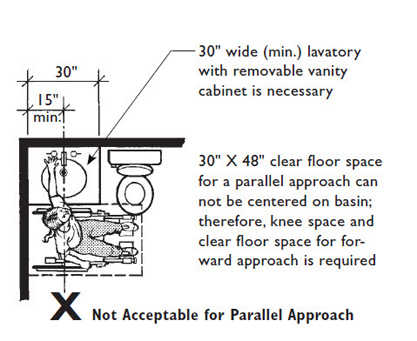

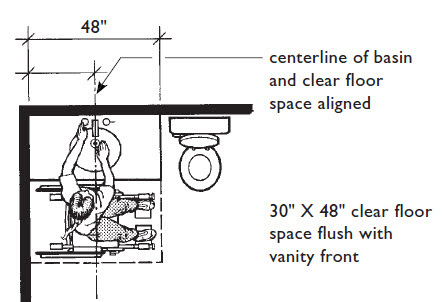

Fair Housing Clear Floor Space Bathroom Lavatories

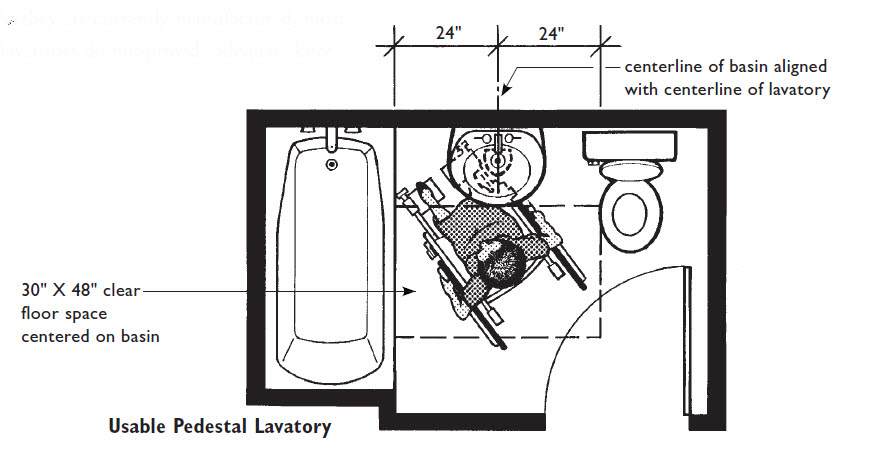

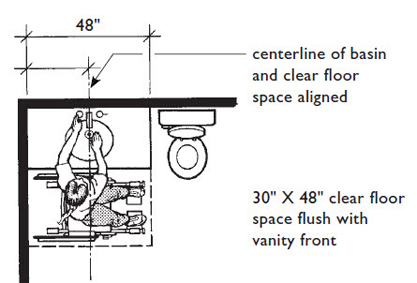

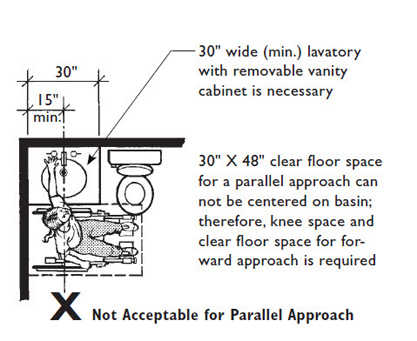

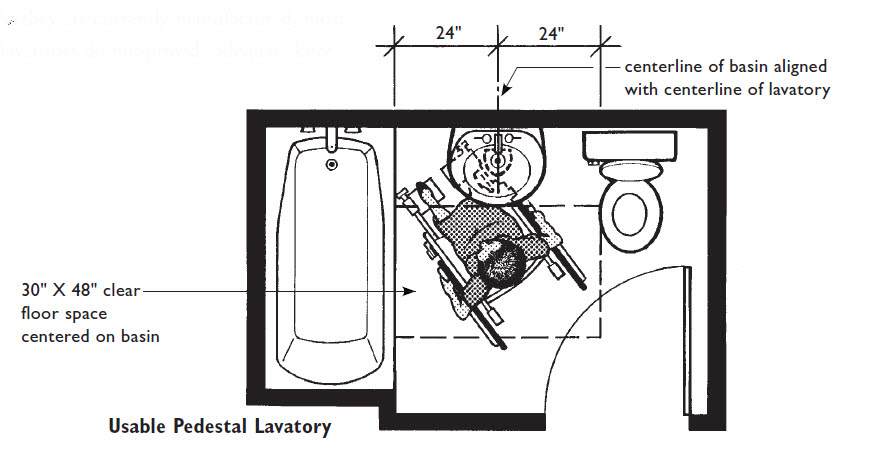

A 30-inch x 48-inch clear floor space is required at the lavatory so a person who uses a wheelchair or scooter can get close enough to the basin and controls to use the fixture. When knee space is not provided for a forward approach, this 30-inch x 48-inch clear floor space must be parallel to the cabinet or counter front and centered on the basin.

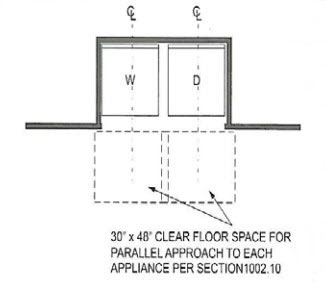

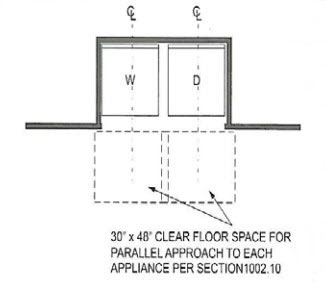

ANSI A117.1 Washer and Dryer

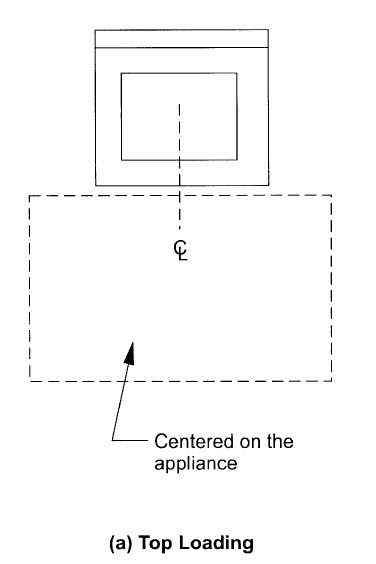

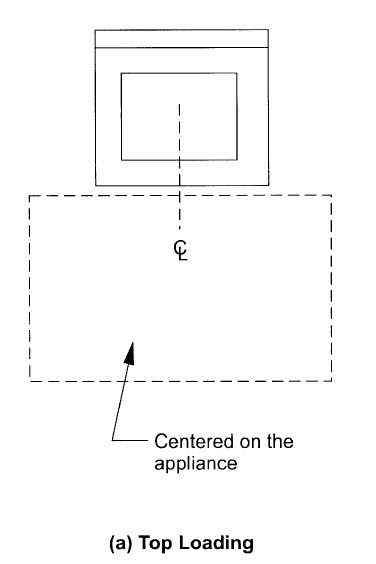

611.2 Clear Floor Space. A clear floor space complying with Section 305, positioned for parallel approach, shall be provided. For top loading machines, the clear I floor space shall be centered on the appliance. For front loading machines, the centerline of the clear floor space shall be offset 24 inches (610 mm) maximum from the centerline of the door opening.

ANSI A117.1 Residential Kichen Work Surface

In kitchens of residential dwelling units there is a requirement to provide a “work surface” with a knee clearance with a floor space centered and allowing a forward approach.

804.3 Kitchen Work Surface (Residential only)

804.3.1 Clear Floor or Ground Space. A clear floor space complying with 305 positioned for a forward approach shall be provided. The clear floor or ground space shall be centered on the kitchen work surface and shall provide knee and toe clearance complying with 306.

The image above shows a residential kitchen with a sink as well as a “work surface” which provides a forward approach. The work surface is required that the clear floor space below it be centered at the surface. The sink is not required to provide a clear floor space that is centered.

The image above shows a residential kitchen work surface and it is centered at the surface.

Thursday, September 1st, 2022

Part 2

We have been discussing when we should make our clear floor space centered on the elements. This is a continuation of the commercial guidelines outlined in the ADA. For Part 1 refer to the

August Newsletter.Below are some other instances that the ADA will require that there be a clear floor space that is centered.

Residential Kichen Work Surface

In kitchens of residential dwelling units (not located in multi-family housing, but required by section 233 to be accessible, there is a requirement to provide a “work surface” with a knee clearance with a floor space centered and allowing a forward approach.

804.3 Kitchen Work Surface (Residential only)

804.3.1 Clear Floor or Ground Space. A clear floor space complying with 305 positioned for a forward approach shall be provided. The clear floor or ground space shall be centered on the kitchen work surface and shall provide knee and toe clearance complying with 306.

The image above shows a residential kitchen with a sink as well as a “work surface” which provides a forward approach. The work surface is required that the clear floor space below it be centered at the surface. The sink is not required to provide a clear floor space that is centered.

The image above shows a residential kitchen work surface and it is centered at the surface.

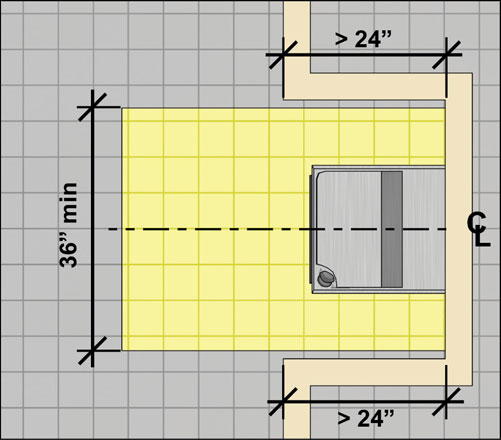

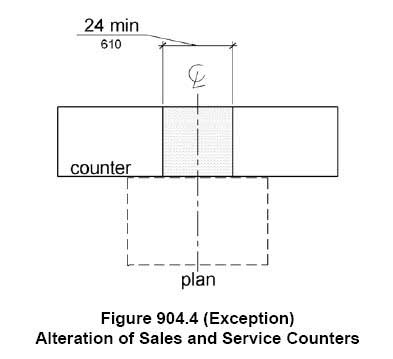

Altered Sales and Service counter

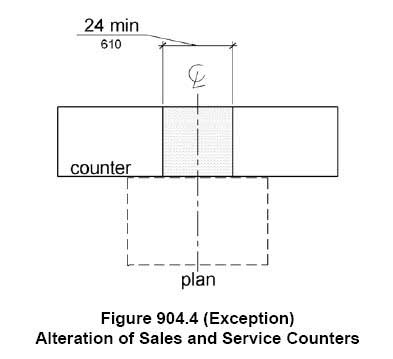

When an existing sales and service counter is altered, they must provide an accessible portion. Typically a sales or service counter must be 36″ long minimum, but if they cannot accommodate that length they would be allowed to only provide a 24″ counter as long as there is a clear lfoor space centered and parallel to the counter.

904 Sales and Service counters

904.4 Sales and Service Counters.

EXCEPTION: In alterations, when the provision of a counter complying with 904.4 would result in a reduction of the number of existing counters at work stations or a reduction of the number of existing mail boxes, the counter shall be permitted to have a portion which is 24 inches (610 mm) long minimum complying with 904.4.1 provided that the required clear floor or ground space is centered on the accessible length of the counter.

The image above shows an example of a counter which has a parallel approach at the lower counter and the clear floor space is also centered at the accessible portion. The length is unknown, but this would be an example of how the exception could be taken.

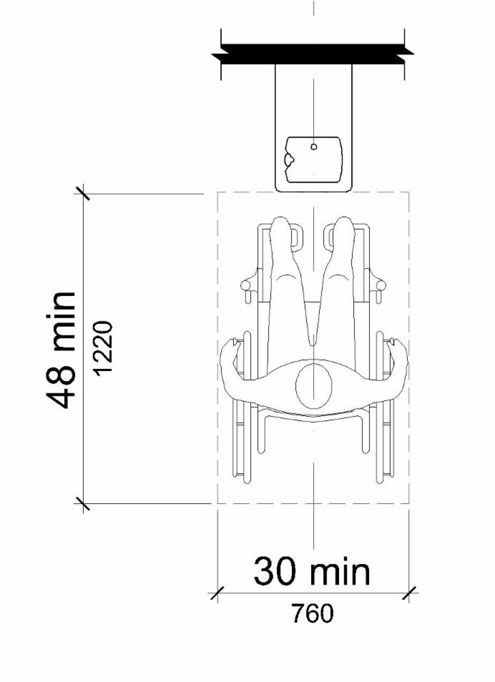

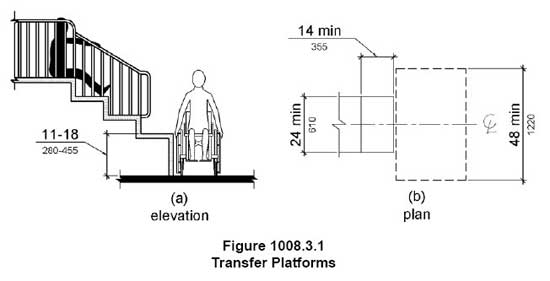

Playground transfer system

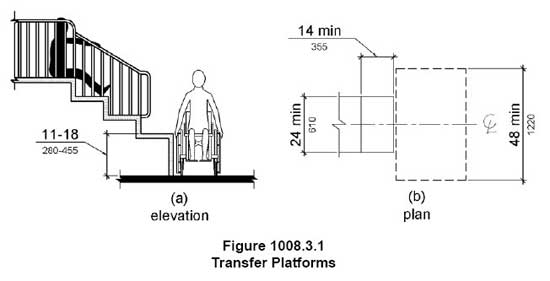

When playgrounds have elevated components that require an accessible route, one way that they can reach the elevated portion is via a transfer system. That transfer system will also require to have a parallel clear floor space centered at the platform.

1008.3Playground Transfer Systems

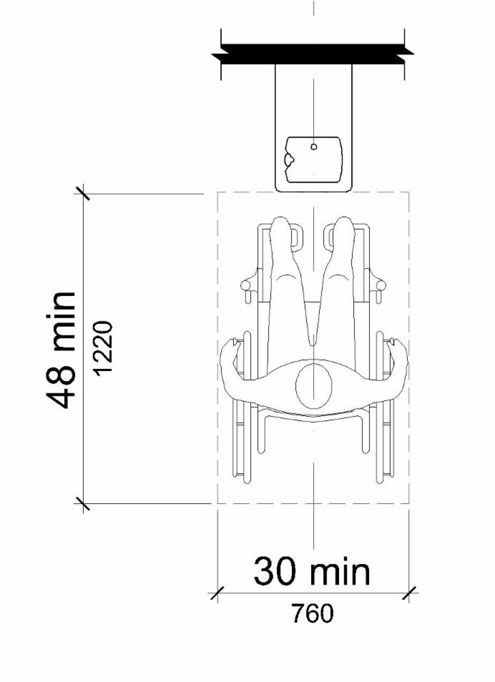

1008.3.1.3 Transfer Space. A transfer space complying with 305.2 and 305.3 shall be provided adjacent to the transfer platform. The 48 inch (1220 mm) long minimum dimension of the transfer space shall be centered on and parallel to the 24 inch (610 mm) long minimum side of the transfer platform. The side of the transfer platform serving the transfer space shall be unobstructed.

The image above shows a transfer system at an elevated play structure. There is room for the clear floor space to be centered at the platform.

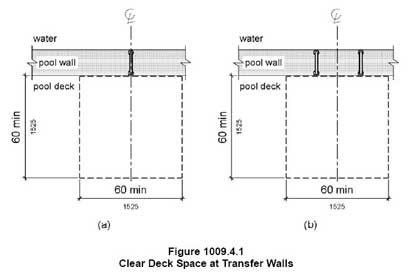

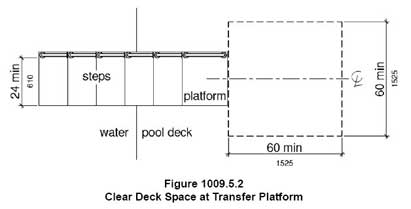

Pool transfer walls and platforms

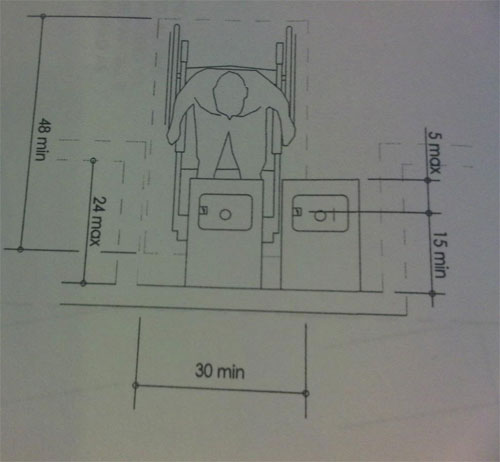

Pools and spas (jacuzzis/hot tubs) are required to have an accessible entry (or two depending on the size of the pool). There are several options for the accessible entry. One is a transfer wall and another a transfer platform. The transfer wall or the transfer platform must have a clear floor space centered at the deck to assist with entry to the pool.

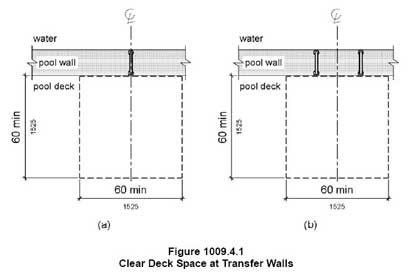

1009.4 Pool Transfer Walls

1009.4.1 Clear Deck Space. A clear deck space of 60 inches (1525 mm) minimum by 60 inches (1525 mm) minimum with a slope not steeper than 1:48 shall be provided at the base of the transfer wall. Where one grab bar is provided, the clear deck space shall be centered on the grab bar. Where two grab bars are provided, the clear deck space shall be centered on the clearance between the grab bars.

The image above shows a transfer wall with two grab bars at a jacuzzi. There is room for the clear floor space to be centered between the two grab bars.

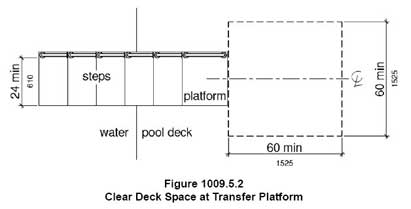

1009.5 Pool Transfer Platform

1009.5.2 Transfer Space. A transfer space of 60 inches (1525 mm) minimum by 60 inches (1525 mm) minimum with a slope not steeper than 1:48 shall be provided at the base of the transfer platform surface and shall be centered along a 24 inch (610 mm) minimum side of the transfer platform. The side of the transfer platform serving the transfer space shall be unobstructed.

1) Texas Association of Interior Design

Ludowici Dallas Design Center | 133 Manufacturing St, Dallas, TX 75207

Monday, August 1st, 2022

Part 1

In the 2010 ADA and the 2012 Texas Accessibility Standards there are certain elements that require front approach and centered clear floor space on the element, but not all of them do. This newsletter will enumerate the one’s that do. Other elements such as lavatories and sinks only require forward approach but the clear floor space is not required to be centered.

Below are the elements that require a clear floor space to be centered:

Drinking fountains

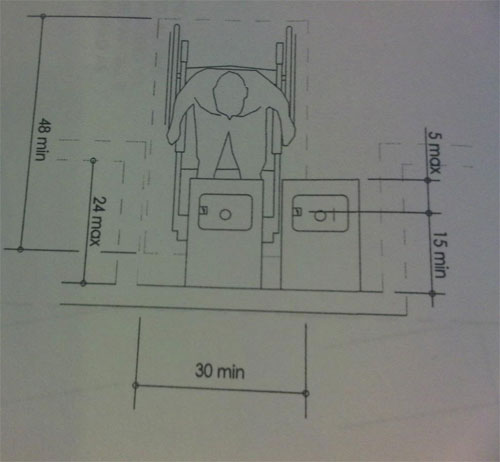

Drinking fountains are one of the elements listed in the ADA and TAS that require that the wheelchair drinking fountain have a clear floor space centered on the unit. The clear floor space must also be a forward approach.

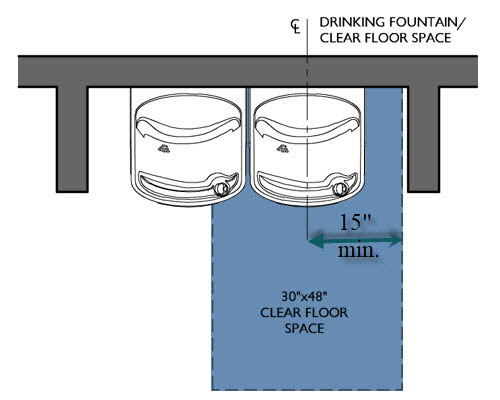

602 Drinking Fountains

602.2 Clear Floor Space. Units shall have a clear floor or ground space complying with 305 positioned for a forward approach and centered on the unit. Knee and toe clearance complying with 306 shall be provided

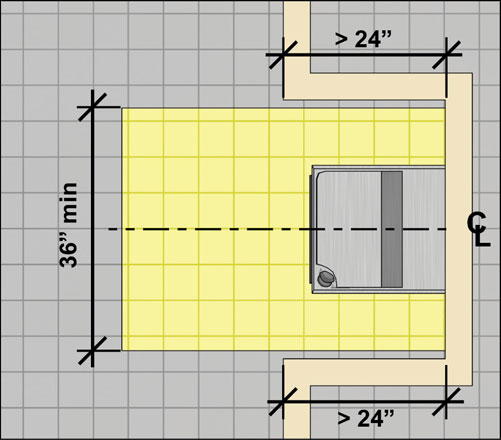

The image above shows the required clear floor space at the drinking fountain. It must be a forward approach and it must be centered on the wheelchair accessible drinking fountain. If it is located at an alcove deeper than 24″ the clear floor space must be widened to 36″ wide.

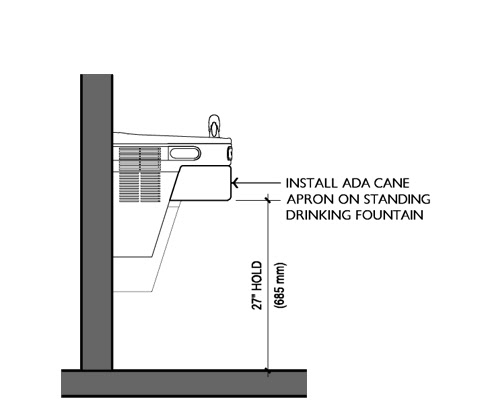

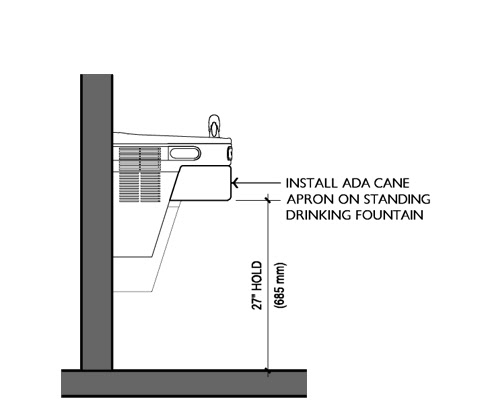

There are two violations that occurr with this requirement. One is that sometimes the drinking fountains are located along a corridor and not in an alcove. This creates a protruding object issues (see this newsletter that explains that). In order to resolve the protruding object, a cane dectable apron is sometimes installed at the bottom of the “high” drinking fountain and the apron reduceds the ability to have a forward approach because it might be lower than 27″ a.f.f.

The image above shows how the clear floor space centered under the “low” drinking fountain spans below the “high” one and if there is an apron below the 27″ a.f.f. it will prevent the use of the drinking fountain by a wheelchair.

Number two is that sometimes the drinking fountains are located in an alcove and the walls creating the alcove reduce the 30″ clearance which must be centered. The wall adjacent to the wheelchair accessible drinking fountain should be a minimum distance of 15″ from the centerline of the drinking fountain to the inside of the wall.

The image above shows how the clear floor space centered under the “low” drinking fountain must be a minimum of 15″ from the center of the drinking fountain to the inner edge of the alcove.

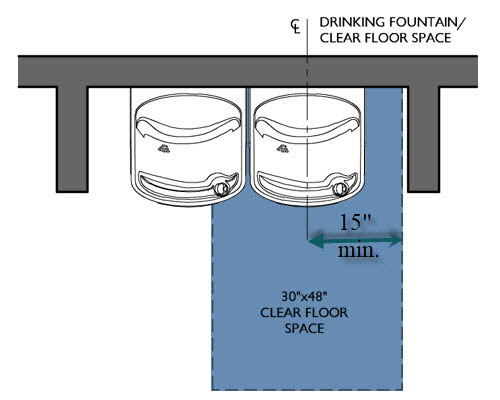

Washer and Dryer

The washer and dryer must also have the clear floor space centered on the appliance and must have parallel approach.

611 Washer and Dryer

611.2 Clear Floor Space. A clear floor or ground space complying with 305 positioned for parallel approach shall be provided. The clear floor or ground space shall be centered on the appliance.

This sometimes causes issues if the washer and dryer are located inside a closet. The doors may reduce the clearance.

The image above shows a set of washer and dryer located inside a utility closet. The doors do not open 180 degrees and reduce the clear floor space to less than 24″ from the centerline of the dryer to the edge of the floor space.

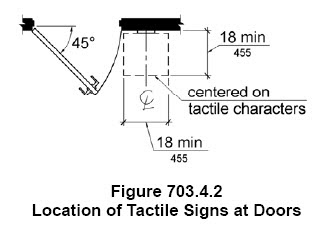

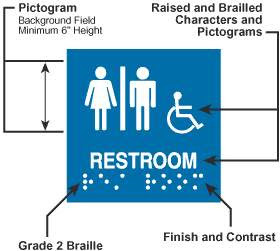

Signage

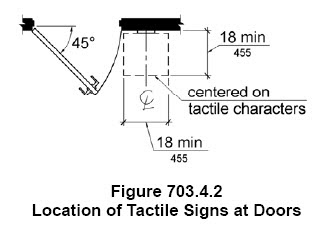

The signage that designate permanent rooms must have an 18″x18″ clear floor space centered on the sign.

703 Signage

703.4.2 Location. ….Signs containing tactile characters shall be located so that a clear floor space of 18 inches (455 mm) minimum by 18 inches (455 mm) minimum, centered on the tactile characters, is provided beyond the arc of any door swing between the closed position and 45 degree open position.

The image above shows a sign which has a drinking fountain in front of it, therefore the requirement for a clear floor space centered on the sign has not been met.

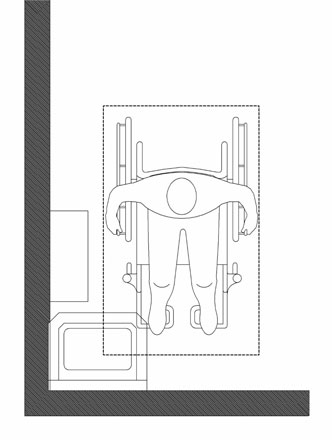

Lavatories and Sinks

One of the misconceptions is that a clear floor space at the sink or lavatory is required to be centered. The approach must be forward, but the clear floor space is not noted as needing to be centered, like the other sections do. Therefore by omission we understand that the clear floor space can be offset.

606 Lavatories and Sinks

606.2 Clear Floor Space. A clear floor space complying with 305, positioned for a forward approach, and knee and toe clearance complying with 306 shall be provided.

The image above shows a wheelchair clear floor space that is not centered at the lavatory. The clear floor space under the lavatory can be offset if there is an obstruction such as a paper towel dispenser next to the lavatory.

Wednesday, June 1st, 2022

Introduction:

Accessible signage can be a very confusing topic. Even after all these years of practicing my accessibility consulting, I am still learning a thing or two. Sadly they can even be confusing to signage manufacturers and installers.

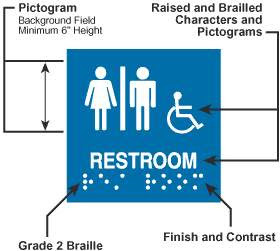

Accessible signs require the following things:

- Raised and Brailled Characters

- Contrasting background

- San Serif Fonts

- If using Pictogram, there are requirements

- If depicting accessible spaces the use of the ISA (International Symbol of Access)

This newsletter will focus on a few common errors I encounter during my inspections.

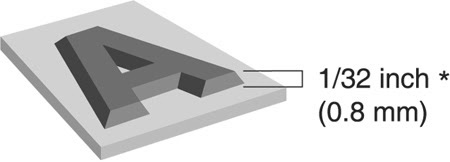

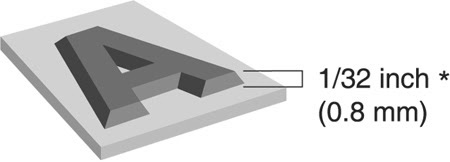

Raised Characters

The accessible signage will require that the characters describing the space whether it be a number or letters, must be raised. They should be at least 1/32″ above the surface of the sign.

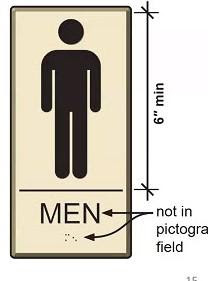

This graphic shows the minimum requirement for the raised characters of a sign.

There should also be Braille below the words that states the same words that are provided. So all words and numbers should be duplicated by Braille

The restroom had a painted sign on the door but the characters were not raised and it did not have brailled as a duplicate. This is not compliant

The restroom sign has both raised letters and characters and braille duplicated below the words. This is a compliant sign..

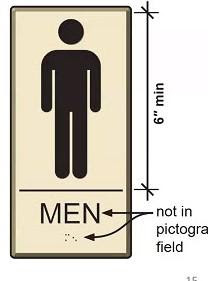

Pictograms

What are pictograms? It is a figure that represents the words of the sign. Pictograms are not required, but if you use them the field they are in should be 6″ minimum. The pictogram can be smaller than that, but the field must be at least 6″ tall.

Pictograms must be located ABOVE the words they are describing. Per section 703

703.6.3 Text Descriptors. Pictograms shall have text descriptors located directly below the pictogram field. Text descriptors shall comply with 703.2, 703.3 and 703.4.

The pictogram at this sign is located below the words describing it. That is not compliant

Monday, May 2nd, 2022

Introduction:

Changes to the Texas Accessiblity Standards have been proposed and are open for public comments. The new standard, once adopted would be called The 2022 Texas Accessibility Standards.

This newsletter will give you a few proposed changes. These have not been adopted yet, and if you have any comments for TDLR before they implement them, the comments will be accepted until May 9th, 2022 using this link

2022 Texas Accessibility Standards Changes

Here are a few of the changes that are being proposed:

1. Outdoor Developed Areas. There will be a brand new chapter for Outdoor developed areas, Section 245 and Chapter 11. These will include trails, beaches, camping and picnic areas (just to name a few).

2. Advisory. Many of the advisories have become part of the Standards

3. Definition of Alteration. The definition of “alteration” has change slightly to include clarification on “circulation paths”. It now includes flooring as part of the definition:

106.5.5 Alteration. A change to a building or facility that affects or could may affect the usability of the building or facility or portion thereof. Alterations include, but are not limited to, remodeling, renovation, rehabilitation, reconstruction, historic restoration, resurfacing of circulation paths or vehicular ways including carpets, floors, or fields, changes or rearrangement of the structural parts or elements, and changes or rearrangement in the plan configuration of walls and full-height partitions.

Normal maintenance, reroofing, painting or wallpapering, or changes to mechanical and electrical systems are not alterations unless they affect the usability of the building or facility

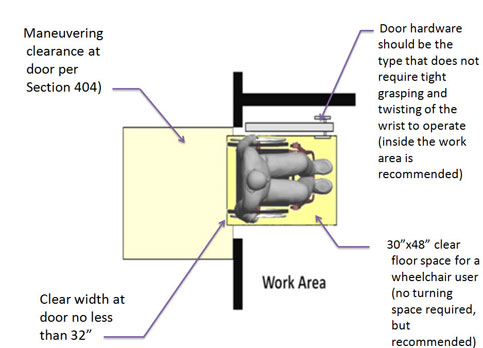

The exemption for employee work areas clarified what “approach, enter and exit” means

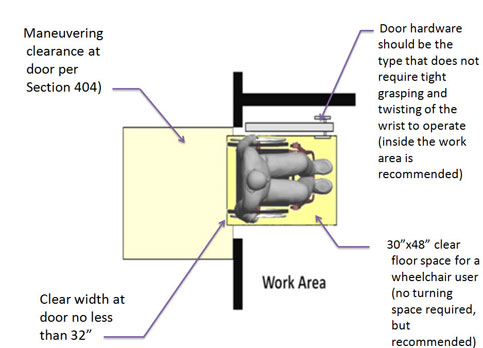

203.9 Employee Work Areas. …..

“Approach, enter, and exit” means that people using wheelchairs must be able to enter and back out of the space. Employee work area doors, doorways, and gates, therefore, must comply with TAS 404 except the maneuvering clearance is limited to the “enter” side unless required for egress by TAS 207.1.

The picture above shows the diagram which explains the requirements for a work area entrance.

4. Licensed Physical and Occupational Therapy spacesused to have to go through a variance process in order to allow them not to be accessible. The proposed changes makes them not required and will no longer need a variance.

203.15 Licensed Physical and Occupational Therapy Training Areas Including Bathrooms and Kitchens. Licensed provider areas that are purposefully inaccessible for the intent of training persons with disabilities to function in a simulated home environment for when they leave therapy and return home shall not be required to comply with accessible features. The user must be able to get to the area but may not necessarily be required to provide an accessible route within the space for training purposes.

Physical Therapy areas will no longer require a variance not to comply

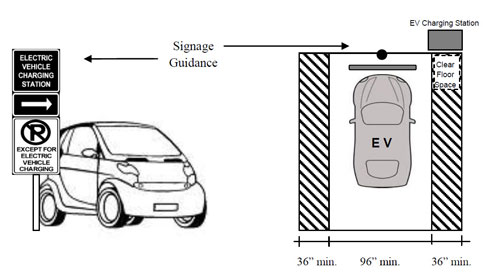

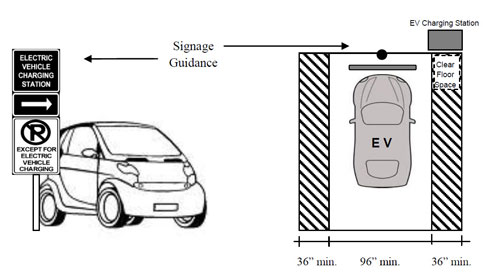

5. Electrical Vehicle Charging Stations. TDLR has issued many Technical Memos throughout the years. The 2022 TAS will incorporate some as part of the standards. One of them is about Electrical Vehicle parking and charging spaces. The requirements will now be part of the 2022 TAS in section 244, 208 and 502.

This is the requirements from the Technical Memo for Electrical Vehicle Charging Stations. They will now be part of the new standards

.

.

A built example

A charging station. The 2022 TAS will require a clear floor space to reach the accessible one.

6. 208.1 Parking Facilties. TDLR has clarified that parking facilities that are served by valet parking are not exempted from compliance with 208 and must have accessible parking.

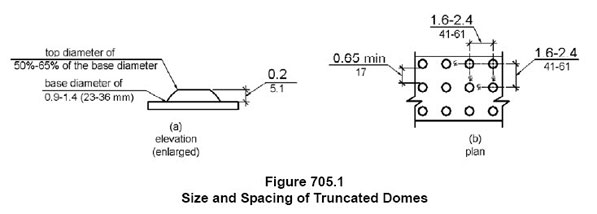

7. Curb ramps at public right of way. THEY’RE BACK!!! Detectable warnings (truncated domes with contrasting color) are being proposed to come back on the Standards. Don’t kill me!

curb ramps located within the public right of way are proposed to have detectable warnings.

Be sure you get involved in the public comments. We need your voices and opinions to be heard to ensure that the Standards are clear and are providing proper guidance for design professionals so we can design and build environments for persons with disabilities that are inclusive and safe.

Friday, April 1st, 2022

Introduction:

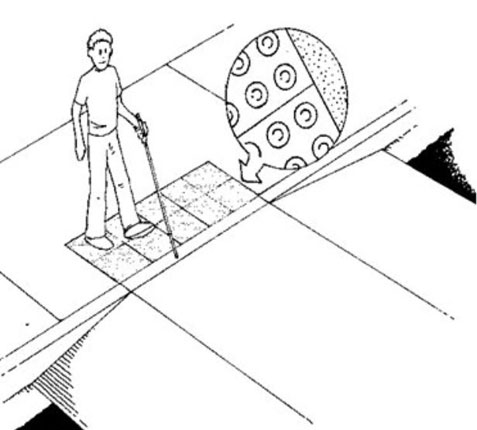

If you have been around for a minute in the building industry you have seen our esteemed “truncated domes” come and go, and come and go…well it happened again….When the ADAAG was published in 1991, there was a section called “Detectable Warnings”. These were elements used for people that were visually impaired to assist them in navigating their exterior environment. A detectable warning had texture and contrasting color so a person who used a cane could feel the texture as he walked and maybe if they had low vision they could detect a change in color. Both of these methods allowed them to be aware that there might be a hazard on its way.

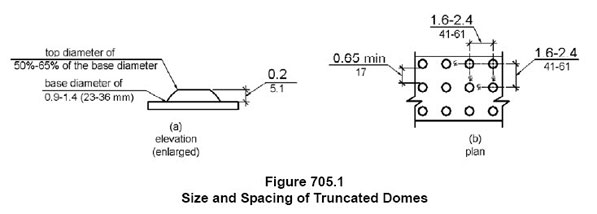

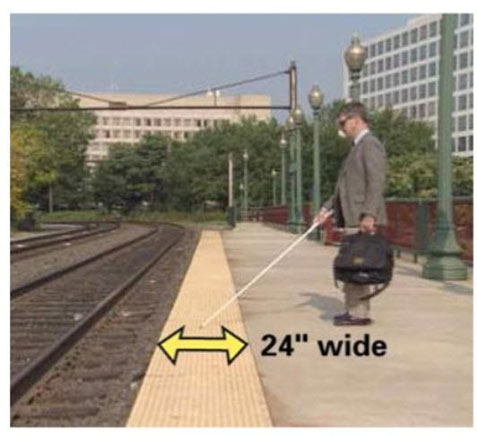

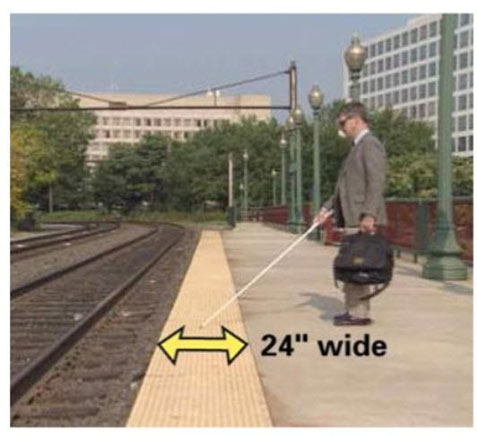

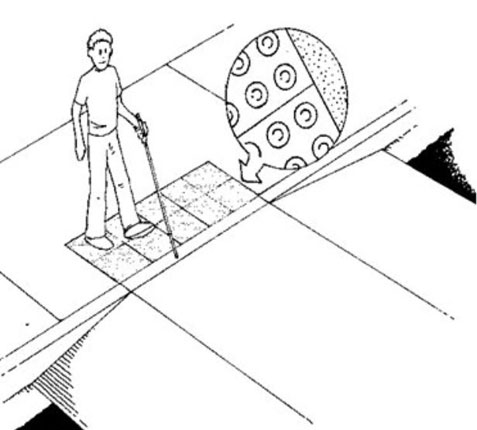

The detectable warning texture was required to be “truncated domes” located at a curb ramp and later it was added to pedges at a train track platforms.

This is a curb ramp inside the property line with detectable warnings.

This is a train platform edge with detectable warnings.

The ADA Standards for Accessible Design and the Texas Accessibility Standards

After the 2010 ADA Standards for Accessible Design was passed into law, the rules about detectable warnings changed. Before, detectable warnings were required at curb ramps. The new version now only requires it at train platform edges. Curb ramps inside of the property line (which is all that ADA regulates) will no longer require texture or color on it.

The picture above built in microwaves mounted above the 48″ allowable reach range. They added a counter top microwave that was not built in. This does not alleviate the lack of reach range.

Public Right of Way

The Public Right of Way guidelines (which are only proposed and have not been adopted), as well as municipalities and Department of Transportation may require that detectable warnings be provided at the bottom 24″ of the curb ramp. This will allow people that are visually impaired be aware that there might be a hazard beyond the texture.

The ADA does not have requirements beyond the property line. Therefore the public right of way does not fall under the ADA.

The Texas Department of Licensing and Regulation used to have a section in Chapter 68 which required detectable warnings at curb ramps within the public right of way, but they eliminated that in the most current version of the Rules. Click Here to see what they require.

TDLR no longer requires detectable warning at curb ramps at the public right of way.

The figure above shows the requirement for detectable warnings listed in the Public Right of Way Guidelines

The curb ramp has detectable warnings per the Department of Transportation and the Public Right of Way Guidelines. Check your municipality to make sure what it requires

Tuesday, March 1st, 2022

Introduction:

I perform ADA, Fair Housing and Texas Accessibility Standards on site inspection and assessments every Wednesday. Some days I find unique conditions that I like to share with you so we can learn from them and be sure they do not happen to you also. This newsletter will give you some of my latest intersting finds.

Vision Lights at Doors

The ADA requires that all doors that require user passage comply with all the portions of the section 404. Door that reqired “user passage”

But are all doors required to comply? What about doors that are only used for employees? The doors shown below are into a commercial kitchen. The vision lights for doors that allow user passage must be mounted no higher than 43″ a.f.f., but these type of doors have the vision light mounted higher. Here is the standard:

404.2.11 Vision Lights. Doors, gates, and side lights adjacent to doors or gates, containing one or more glazing panels that permit viewing through the panels shall have the bottom of at least one glazed panel located 43 inches (1090 mm) maximum above the finish floor.

The vision lights requirement are for ALL doors that require user passage unless the room beyond is excempted (like IT closets or other machinery spaces). Employee work area doors must have the ability to approach, enter and exit, therefore those doors into employee work areas like commercial kitchens will also have to comply.

During one of my inspections, I went to a restaurant and they had the door into the kitchen with vision lights higher than 43″ a.f.f. The owner was confused. It is not so simple to understand why this door would have to comply, but keep in mind that the ADA protects persons with disabilities from discrimination at the work place. If a person in a wheelchair gets hired as manager, the vision light allows them to see inside so they don’t get hit by the door. Be sure to specify one of the doors with the vision lights lower.

The picture above shows a commercial kitchen door with vision lights mounted higher than 43″ a.f.f. This is not compliant.

The picture above shows a commercial kitchen door with vision lights mounted lower than 43″ a.f.f. This is compliant.

Fixed or Built in elements

The ADA only deals with fixed or built in elements. At one of my inspections there was a break room with built in microwaves that were mounted higher than the allowable reach range. To solve the violation they added a microwave to the counter. This did not resolve the violation, because it is not a “built in” element and does not satisfy the requirement. Below is what the ADA states about what elements are scoped in the standards:

“Scope of coverage. The 1991 Standards and the 2010 Standards apply to fixed or built-in elements of buildings, structures, site improvements, and pedestrian routes or vehicular ways located on a site. Unless specifically stated otherwise, the advisory notes, appendix notes, and figures contained in the 1991 Standards and the 2010 Standards explain or illustrate the requirements of the rule; they do not establish enforceable requirements.”

The picture above built in microwaves mounted above the 48″ allowable reach range. They added a counter top microwave that was not built in. This does not alleviate the lack of reach range.

Protruding Objects

There are rules in the ADA Standards that pertain to people who are visually impaired. Since they cannot detect objects mounted higher than 27″ a.f.f. we typically design and built the objects so that they are recessed or have some sort of cane detection. But in one of my inspections, the drinking fountain was recessed, but not far enough, so that the leading edge was still projecting onto the circulation path more than 4″

The picture above shows a recessed drinking fountain that is located in a corridor. But the leading edge still projects more than 4″ onto the circulation path and therefore was considered a violation of the protruding object rule

The drinking fountain projects 5″ ontothe circulation path

Monday, February 7th, 2022

When is an elevator required?

The ADA Scoping section 206.2.3 Multi-Story Buildings and Facilities requires that there will be an accessible route connecting all stories or mezzanines in a multi-story building:

“206.2.3: At least one accessible route shall connect each story and mezzanine in multi-story buildings and facilities.”

An accessible route can be provided throught a ramp or elevator. There are some times when the accessible route can be a wheelchair lift, but they are limited to what Section 206.7

This is the Ed Roberts Campus building in Berkley California

This is an example of a platform lift-there are restrictions on when you can use one

This is an example of an elevator. There are also exceptions one can take on what type of elevator you can use.

There is another section of the Standards that requires an accessible route in a n alteration where a new stair is added to connect two stories:

206.2.3.1 Stairs and Escalators in Existing Buildings. In alterations and additions, where an escalator or stair is provided where none existed previously and major structural modifications are necessary for the installation, an accessible route shall be provided between the levels served by the escalator or stair unless exempted by 206.2.3 Exceptions 1 through 7.

In the photo above, the retail store added a stair to connect to the story above. An elevator would have to be provided to connect to the second story. If there is already an elevator in the building outside the store, it is acceptable (although not advisable) to use that elevator. But if the building does not have an elevator, one must be provided inside the store.

EXCEPTIONS: There are certain instances when an accessible route will not be required. Below are some of those exceptions:

ADA Section 206.2.3 EXCEPTION:

1. In private buildings or facilities that are less than three stories or that have less than 3000 square feet (279 m2) per story, an accessible route shall not be required to connect stories provided that the building or facility is not a shopping center, a shopping mall, the professional office of a health care provider, a terminal, depot or other station used for specified public transportation, an airport passenger terminal, or another type of facility as determined by the U. S. Attorney General. ……

This exception is only for privately owned buildings which have two stories only. If they have more than two stories, in order to take the exception each stroy has to be less than 3,000 square feet per story.

But also the exception removes shopping centers or shopping malls. So even if the shopping center is only two stories tall, they must provide an accessible route.

This is a two story shopping center. An elevator will be reqired to reach the second floor

The other exceptions are for public buildings owned by a State or Local government or publically funded.

2. Where a two story public building or facility has one story with an occupant load of five or fewer persons that does not contain public use space, that story shall not be required to be connected to the story above or below.

This means that any public building that is two stories and has more than five occupants on the second story will have to have an elevator connecting the stories.

This is a picture of a municipality office on the second floor which has less than 5 occupants in that floor.

And another exception is of historic buildings that are more than two stories

7. Where exceptions for alterations to qualified historic buildings or facilities are permitted by 202.5, an accessible route shall not be required to stories located above or below the accessible story.

A new lab counter in an existing science classroom is an alteration to an area containing a primary function

Some other exceptions are for residential facilities, multi-story rooms in a transient lodging, detention and correctional facilities, air traffic control towers.

There are other requirements for accessible routes that are beyond the scope of this newsletter, but we will make one in the next few months.

Tuesday, January 4th, 2022

Click here to view the introduction video to explain the requirements for alterations in the ADA

Introduction:

One of the things that is confusing to some of my clients is the requirements for “alterations”. The ADA Standards for Accessible Design applies to certain types of buildings: Commercical Facilities and Public Accommodations that are built new or existing buildings, facilities or elements that are “altered”.

ADA 101.1 General. The requirements are to be applied during the design, construction, additions to, and alteration of sites, facilities, buildings, and elements to the extent required by regulations issued by Federal agencies under the Americans with Disabilities Act of 1990 (ADA).

ADA 201.1 Scope. All areas of newly designed and newly constructed buildings and facilities and altered portions of existing buildings and facilities shall comply with these requirements.

Basically, the ADA requires that not only new construction comply with the Standards, but also remodels and what they call “alteration” projects.

But what is an alteration?

The ADA defines alterations as follows:

Alteration. A change to a building or facility that affects or could affect the usability of the building or facility or portion thereof.

Alterations include, but are not limited to, remodeling, renovation, rehabilitation, reconstruction, historic restoration, resurfacing of circulation paths or vehicular ways, changes or rearrangement of the structural parts or elements, and changes or rearrangement in the plan configuration of walls and full-height partitions.

So if your project meets the definition of alteration, then it must comply with the ADA sections 202.3, 202.4 and 202.5. The newsletter will explain more in detail below.

Below are some examples of “alterations”

The picture above shows new flooring being installed. This is considered re-surfacing of a circulation path. This would meet the definition of alteration

The picture above shows a historic building that will be restored. This would meet the definition of alteration

The picture above shows a building that was damaged and will be re-constructed. This would meet the definition of alteration

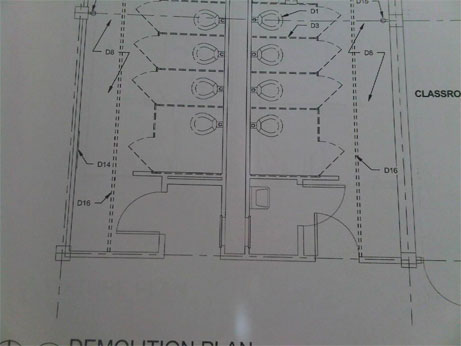

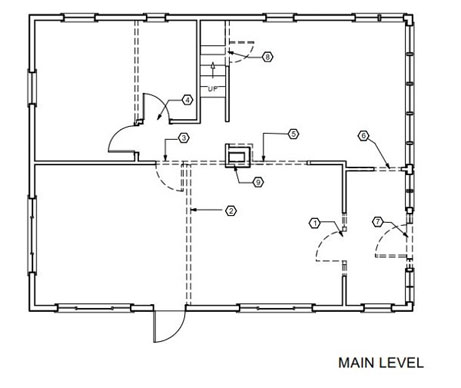

The picture above shows a demolition plan that is removing walls which will essentially reconfigures the plan. This is an alteration

The ADA also tells us what is NOT an altertion:

(from definition) the Normal maintenance, reroofing, painting or wallpapering, or changes to mechanical and electrical systems are not alterations unless they affect the usability of the building or facility.

The picture above shows a sidewalk that has broken pieces. Correcting the sidewalk would be considered maintenance and not an alteration

Not all “finishes” are exempted from having to comply. Painting vertical surfaces is an example of a project that is not an alteration.

Finishes that affect the “usability” such as flooring will trigger compliance.

What is required when the project is an alteration?

When it is determined that an “alteration” is occuring (based on the definition), then we must follow the requirements in section 202.3 which states:

202.3 Alterations. Where existing elements or spaces are altered, each altered element or space shall comply with the applicable requirements of Chapter 2.

In essense, everything new must comply with the standards. There are three exceptions: elements that are not altered (unless as noted in ADA 202.4 which we will discuss next), when it is technically infeasible (and in some jurisdictions will require a waiver or variance from the AHJ in order to make the determination) and when residential dwelling units that are not required to be accessible are altered.

EXCEPTIONS (listed in 202.3):

1. Unless required by 202.4, where elements or spaces are altered and the circulation path to the altered element or space is not altered, an accessible route shall not be required.

2. In alterations, where compliance with applicable requirements is technically infeasible, the alteration shall comply with the requirements to the maximum extent feasible

3. Residential dwelling units not required to be accessible in compliance with a standard issued pursuant to the Americans with Disabilities Act or Section 504 of the Rehabilitation Act of 1973, as amended, shall not be required to comply with 202.3.

We will focus on Exception #1 which gives us guidance if required by section 202.4. Let’s explore that section:

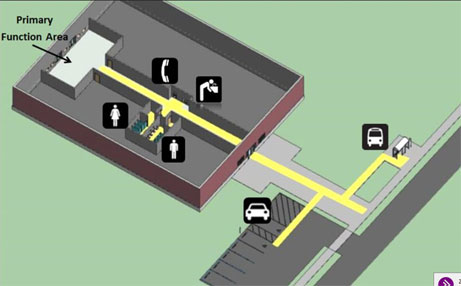

202.4 Alterations Affecting Primary Function Areas.

Before we delved into the additional requirements in section 202.4 it is important to understand what is considered a primary function:

Definition of Primary Function. A major activity for which the facility is intended. Areas that contain a primary function include, but are not limited to, the customer services lobby of a bank, the dining area of a cafeteria, the meeting rooms in a conference center, as well as offices and other work areas in which the activities of the public accommodation or other private entity using the facility are carried out.

Mechanical rooms, boiler rooms, supply storage rooms, employee lounges or locker rooms, janitorial closets, entrances, corridors, and restrooms are not areas containing a primary function.

A building could have many “primary functions”. In a school for example, you would have the primary function of learning, working, performing. So alterations in classrooms, as well as in the administration offices or theater will be considered alterations in areas of primary function.

A new lab counter in an existing science classroom is an alteration to an area containing a primary function

A new dining counter at an existing restaurant is an alteration of an area that contains a primary function

A new reception counter at a lobby is an alteration of an area that contains a primary function

A restroom in an office building or school is NOT a primary function space (unless it is the major activity which the building is intended, such as a rest stop, or a bathroom in a hotel guest room). Thus any alterations within the restroom is not an alteration to an area containing a primary function.

What happens when we our project affects a primary function area?

When an alteration occurrs in an area that contains a primary function, then we not only must follow the requriements of 202.3 (which state that all new elements must comply), but in addition, the path of travel elements that serve the altered area must also comply, even if they are outside the scope of the project.

202.4 Alterations affecting primary function areas. In addition to the requirements of 202.3, an alteration that affects or could affect the usability of or access to an area containing a primary function shall be made so as to ensure that, to the maximum extent feasible, the path of travel to the altered area, including the rest rooms, telephones, and drinking fountains serving the altered area, are readily accessible to and usable by individuals with disabilities, unless such alterations are disproportionate to the overall alterations in terms of cost and scope as determined under criteria established by the Attorney General. In existing transportation facilities, an area of primary function shall be as defined under regulations published by the Secretary of the Department of Transportation or the Attorney General.

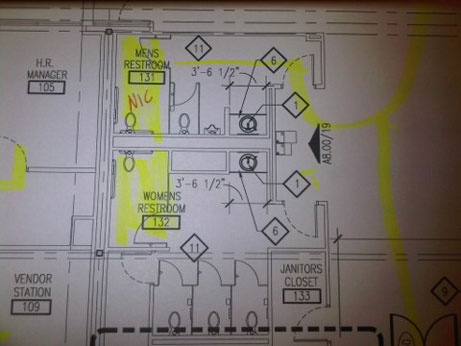

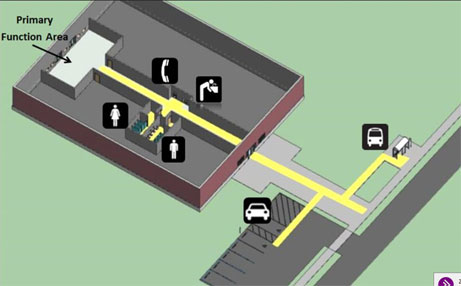

The diagram above shows the yellow line which depicts the path of travel elements leading to the “altered” area. The path of travel begins at the site arrival, then goes to the accessible entrance. It passes existing restrooms, drinking fountains and telephones that serve the altered area. All these existing path of travel elements must comply with the standards.

When a project is going to be done in an area that contains a primary function, and it is an alteration (based on the definition), the scope should include existing path of travel elements that serve the altered area IF they do not comply. There are a couple of exceptions: If the building owner (landlord) is not paying for the tenant’s improvement and if the existing conditions fall in the “Safe Harbor” clause. More on what is a safe harbor, read my newsletter on the subject.

But I am not CHANGING the function….

Many of my clients ask me that question. What if the function of the project stays the same but we are still doing a renovation of the space?

- The definition of alteration has nothing to do with “changing a function”. That terminolgoy appears in the model codes, but not in the ADA. An alteration that affects an area that contains a primary function can remain the same and still trigger compliance with 202.4 path of travel elements.

CASE STUDIES

With the above information, let’s take a look at a few examples and what it would trigger:

Case Study #1: What if we do an alteration in an existing school of an entire bathroom?

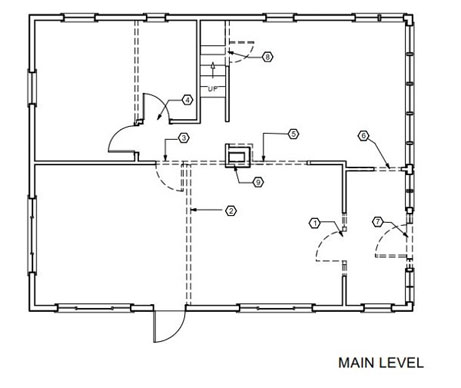

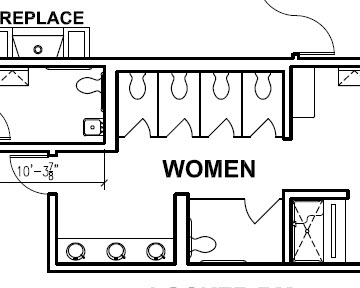

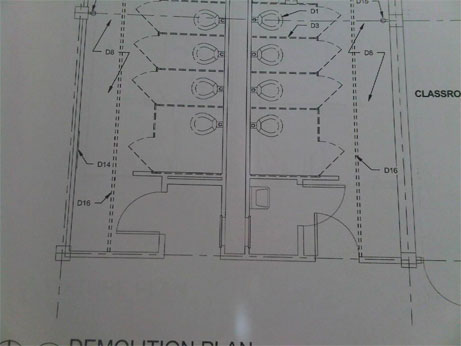

This is an existing school building where they were going to renovate the existing toilet room.

- Restrooms are not a primary function

- They are demo-ing the entire restroom

- They are installing new fixtures and new partitions.

Because the toilet rooms are not a “primary function” in the school, only the new elements installed would have to comply

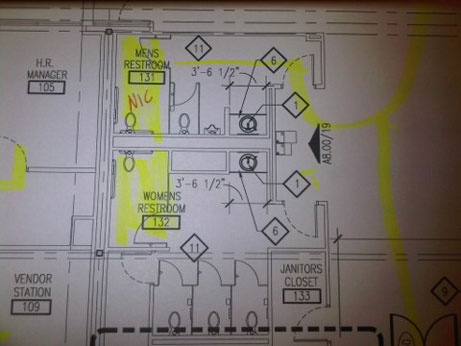

Case Study #2: What if we only renovate one element in the restroom?

This is an existing restroom, but only the lavatory will be altered. Because the ADA allows element by element alteration, only the lavatory will have to comply. The rest of the restroom that was not altered will remain as is and will not be required to be brought up to compliance.

Case Study #3: What if only the toilet is altered?

This one is a little more complicated. Just like with the lavatory, only the toilet would have to comply. But does that mean that it would also require compliant grab bars? What about compliant toilet paper dispenser? The answer is yes. Those are also elements that are part of the water closet.

One gray area question is whether the clearance around the water closet part of the toilet?

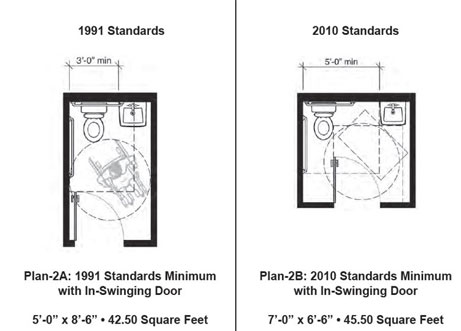

Would the clearance need to be 60″ wide? If the

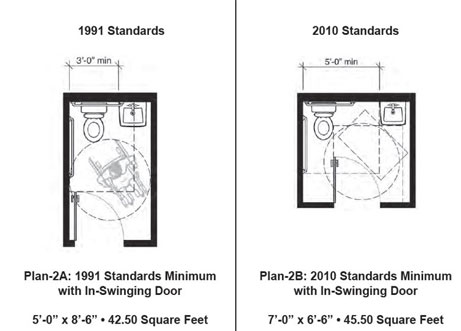

toilet room was built prior to 2012, then it is allowed to remain at 36″ clearance.

The image on the left is the 1991 ADAAG clearance at the toilet. The image on the right is the 2010 ADA Standards clearance at the toilet. If the toilet was built prior to 2012 (the year that the new standard became mandatory) then it is compliant.

Case Study #4: What if new bleachers are installed in an existing gymnasium in the school?

- The gymnasium is a primary function (it is where we learn physical education)

- The bleachers will have to comply

- The path of travel elements that serve the altered area must also comply

Case Study #5: What if we alter the floor at the gymnasium only?

- The gymnasium is a primary function

- The flooring must comply

- The path of travel elements that serve the altered area must also comply

Case Study #6 What if we paint the walls in the gymnasium only

- The gymnasium is a primary function

- Painting doesn’t affect the usability and therefore it is not an alteration

In Summary:

- Altered buildings, facilities and elements must comply

- Altered elements in an area of primary function must comply, plus:

- the Accessible entrance

- the Accessible route

- the Accessible restrooms

- the Drinking fountains

- the Telephones

- But not all of them, just the ones that serve the altered area

- Existing elements that comply with 1991 ADAAG/1994 TAS are a safe harbor

A did a presentation and attached is the .pdf for your information

Abadi

Abadi

.

.