Tolerances and the ADA

Posted on - Monday, November 1st, 2021Are there any allowable tolerances in the ADA?

Construction is not a perfect science. No matter how accurate we try to draw or how careful one is to build and install materials, there will probably always be some error or omission that comes up. Best practices is to allow for the possibility of mistakes by incorporating ranges into our design. That is also what we find in the ADA and other accessibility guidelines.

How does the ADA deal with construction tolerances? First of all the tolerances ONLY apply to “construction”. There are no tolerances allowed in design. Therefore as architects and designers, we must design our spaces with enough room for construction errors. I recommend to my clients to not design to the maximums or minimums written in the Standards.

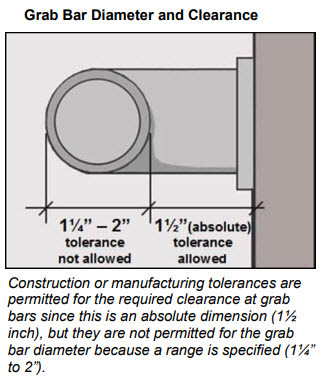

Most dimensions in the ADA Standards are specified as a minimum, maximum, or as a range. In a few areas, absolute dimensions are specified.

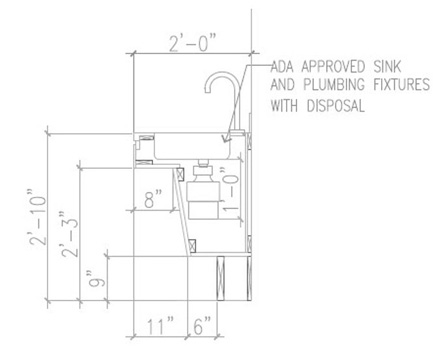

The detail shown above is showing the absolute maximums and minimum dimensions shown in the ADA Standards. There is no room for construction errors. My recommendation is to detail below the maximum and above the minimums so that you build some tolerances prior to construction.

Ranges

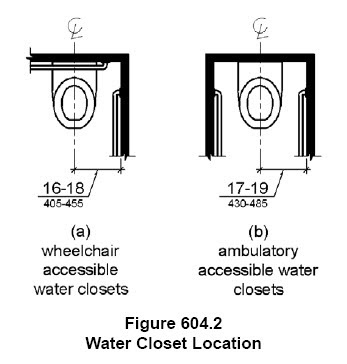

The 2010 ADA provides some requirements with a specified range. For example, the location of the toilet should be between 16”-18”. When a range is stated, it provides an adequate tolerance and therefore no tolerance outside of the range at either point is permitted.

The ADA provides a range for the location of a water closet

This water closet is not compliant because it is located at 18 1/2″ from the side wall to the centerline of the toilet. Even though this water closet is located just 1/2″ beyond the allowable high range, because there was a low and high number as ranges, tolerances are not allowed. Tolerances are built in to the range.

Maximum and Minimums

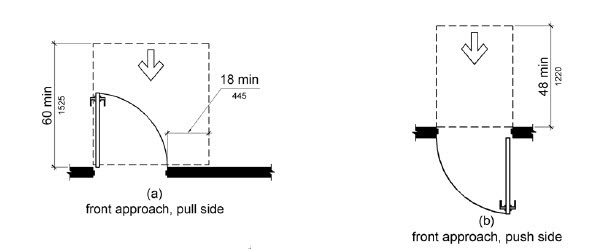

When the ADA states a maximum or a minimum dimension that does not have two specific minimum and maximum end points, tolerances may apply. For example, a door pull side maneuvering clearance is stated to require 18″ min. If the door has a maneuvering clearance that exceeds the minimum allowable dimension instead, it might be allowed according to the amount of lee way given as the industry standard. According to the Access Board, only 3/32″ is allowed as tolerances for door maneuvering clearances.

The ADA figures above show the minimum manevering clearances at the door

The door above has a maneuvering clearance of less than 18″. The clearance is 17″ clearance. Even though it is only 1″ less than what the minimum requires it does not comply with industry tolerances of 3/32″

According to the US Access Board and the Department of Justice, tolerance is an unintended, but permitted (i.e., “tolerated”), variation from a specified dimension resulting from the process of construction or manufacture. The ADA Standards recognize conventional industry tolerances for dimensions not expressed as a range. This applies to field work, not design work. Tolerances necessary for a particular manufacturing process are also permitted. Information on specific tolerances may be available from industry and trade organizations, code groups and building officials, and published references.

The position of the U. S. Access Board – as formalized in the ADA/ABA Guidelines in Section 104.1.1 – is that industry standard tolerances should be relied on when questions regarding this issue arise. However, not many trades have codified specific tolerances for many of the elements mentioned in ADA/ABA Guidelines, nor have they developed accepted industry protocols for measuring when questions of accessibility arise. Our colleagues at Corada has completed research on where to find industry standard tolerances. Here is the link

Absolute dimensions

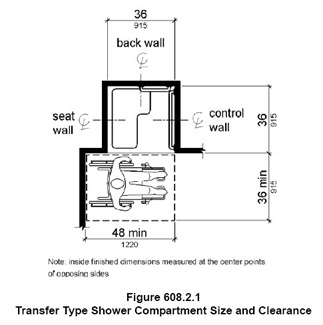

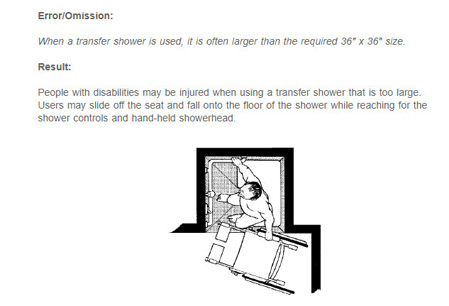

Some dimensions in the ADA are a complete absolute. For example in a transfer shower you are only allowed a 36″x36″ size . There is no maximum or minimums allowed and there is not a range. Therefore industry standard tolerances are allowed. Some manufacturers will make the walls 36″x36″ but the base is narrower.

The shower above was built larger than 36″x36″

The depth of the shower was 39″

The width of the shower was 39″

Sometimes I get asked why is the transfer shower need to be exactly 36″ x36″? Below is the image of the Access Board’s reply. The shower is designed and built so that a person with disabilities can easily and safely transfer onto the shower seat and be able to reach not only the controls but the grab bars as well without much difficulty and without losing balance.

In our research we found that if the shower is constructed of gypsum board, there is a 1/8” tolerance allowed by the industry. This was found in David Kent Ballast, AIA CSI’ Handbook of Construction Tolerance page 198.

Summary

Remember that as you design, allow for construction mistakes (because we all know they happen). There are no tolerances allowances for design mistakes.

If the ADA gives you a range, don’t design to the highest or the lowest number. Always pick a number in the middle.

If the ADA gives you a number not to exceed, then there might be some tolerances, but again do not design to the maximum or minimum number they give you. Always allow for some built in tolerances.

If the ADA gives you an absolute number, then the industry standard tolerances will be able to be used if that number is not achieved. These vary but some references below have codified it.

References

David Kent Ballast, AIA CSI’ Handbook of Construction Tolerance

Abadi

Abadi