Construction Tolerances

Posted on - Friday, July 7th, 2017“But it is only 1/4″ off…”

Construction is not a perfect science. All construction work has tolerances to allow for variations in construction materials and workmanship skills. Zero tolerance in construction is not feasible.

This ramp was obviously not built correctly…the slope exceeds the 1_12″ maximum allowable slope

Tolerance is defined as the:

*permissible range of variation in a dimension of an object

*permissible variation of an object in some characteristic such as hardness, density, or size

*permissible deviation from plan alignment, location or grade.

So knowing this…how does the ADA deal with construction tolerances? First of all the tolerances ONLY apply to “construction”. There are no tolerances allowed in design. Therefore as architects and designers, we must design our spaces with enough room for construction errors.

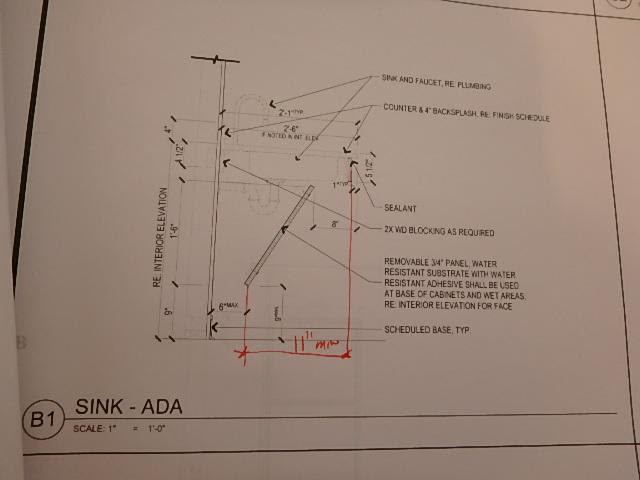

This detail did not have all the dimensions noted which will tell the contractor how to achieve compliance for a knee space per the ADA. If the dimension is not provided_ the contractor might make assumptions and make a mistake in the field.

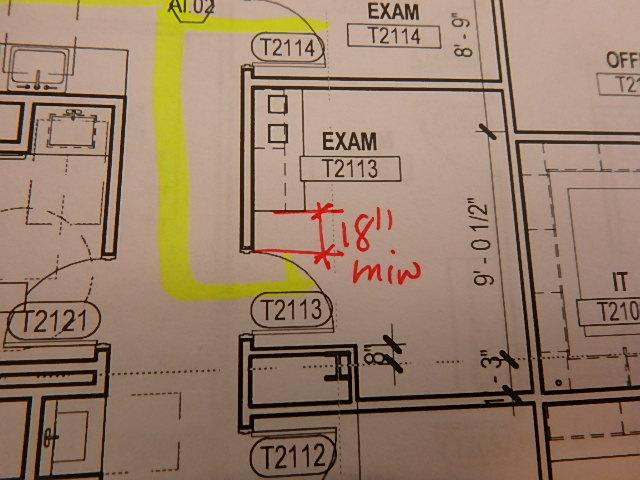

This door did not show the minimum dimension required at the pull side maneuvering. If the drawings do not show this dimension_ the contractor might not build it in a compliant manner.

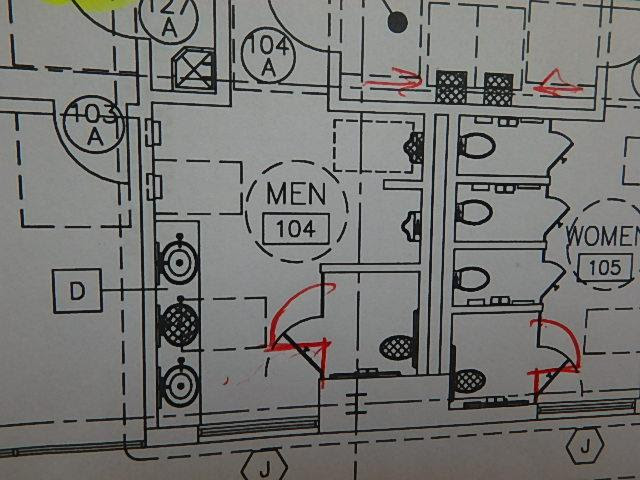

this drawing showed the toilet compartment door in front of the water closet rather than on the opposite corner as required. If the compartment door would have been built per the drawing, there would not be any tolerances allowed to be taken.

The position of the U. S. Access Board – as formalized in the ADA/ABA Guidelines in Section 104.1.1 – is that industry standard tolerances should be relied on when questions regarding this issue arise. However, few trades have codified specific tolerances for many of the elements mentioned in ADA/ABA Guidelines, nor have they developed accepted industry protocols for measuring when questions of accessibility arise. The US Access Board has completed research (‘Dimensional Tolerances in Construction and for Surface Accessibility’). Here is the link

Ranges

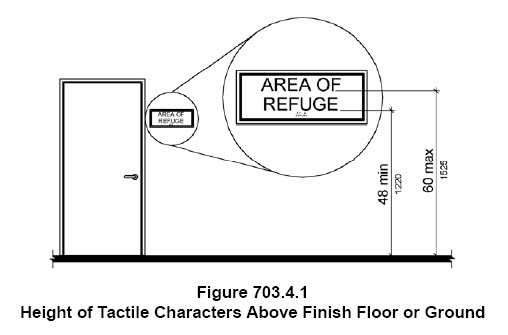

The 2010 ADA provides conventions in their requirements that state a specified range. For example, the location of the signage is between 48″ to 60″ a.f.f. to the bottom of the lowest and highest raised character.

When a range is stated, it provides an adequate tolerance and therefore no tolerance outside of the range at either point is permitted.

This sign was mounted lower than 48″ a.f.f. which is the minimum height allowed. Even though the amount that the sign was off was small, the fact that the ADA provided a range between 48″ minimum and 60″ maximum, the tolerances were already built in by the range provided by the Standards and they cannot deviate.

Maximum and Minimums dimensions

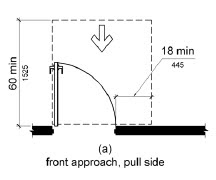

When the ADA states a maximum or a minimum dimension that does not have two specific minimum and maximum end points, tolerances may apply. For example, a door pull side maneuvering clearance is stated to require 18″ min. If the door has a 17 1/2″ maneuvering clearance instead, it might be allowed according to the amount of lee way given as the industry standard.

This figure shows that the maneuvering clearance on the pull side of the door that has a forward approach is 18″ min.

This is a photo of a pull side of the door

The door maneuvering clearance was 17 1/4″ rather than the 18″ minimum required. According to the Access Board, only 3/32″ is allowed as tolerances

Absolute dimensions

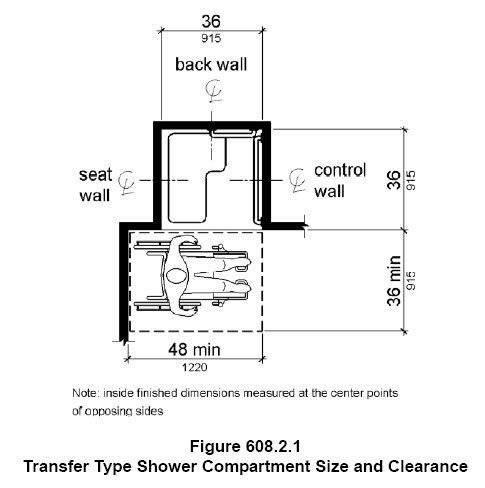

Some dimensions in the ADA are a complete absolute. For example in a transfer shower you are only allowed a 36″x36″ size . There is no maximum or minimums allowed and there is not a range. Therefore industry standard tolerances are allowed.

Some manufacturers will make the walls 36″x36″ but the base is narrower. The Access Board allows a smaller foot print at the base of the shower knowing that the manufacturers products may vary.

Summary

- Remember that as you design, allow for construction mistakes (because we all know they happen). There are no tolerances allowances for design mistakes.

- If the ADA gives you a range, don’t design to the highest or the lowest number. Always pick a number in the middle.

- If the ADA gives you a number not to exceed, then there might be some tolerances, but again do not design to the maximum or minimum number they give you. Always allow for some built in tolerances.

- If the ADA gives you an absolute number, then the industry standard tolerances will be able to be used if that number is not achieved. These vary but some references below have codified it a bit.

References

The US Access Board created a document along with the AIA, CSI and other industry leaders to determine their acceptable industry tolerances for issues related to accessibility. Here is the report

Here is a good article about ADA tolerances by our colleagues at Evan Terry and Associates

Janis Kent, Architect, FAIA, CASp © January, 2016 wrote a blog about tolerances. Here is the link

Abadi

Abadi